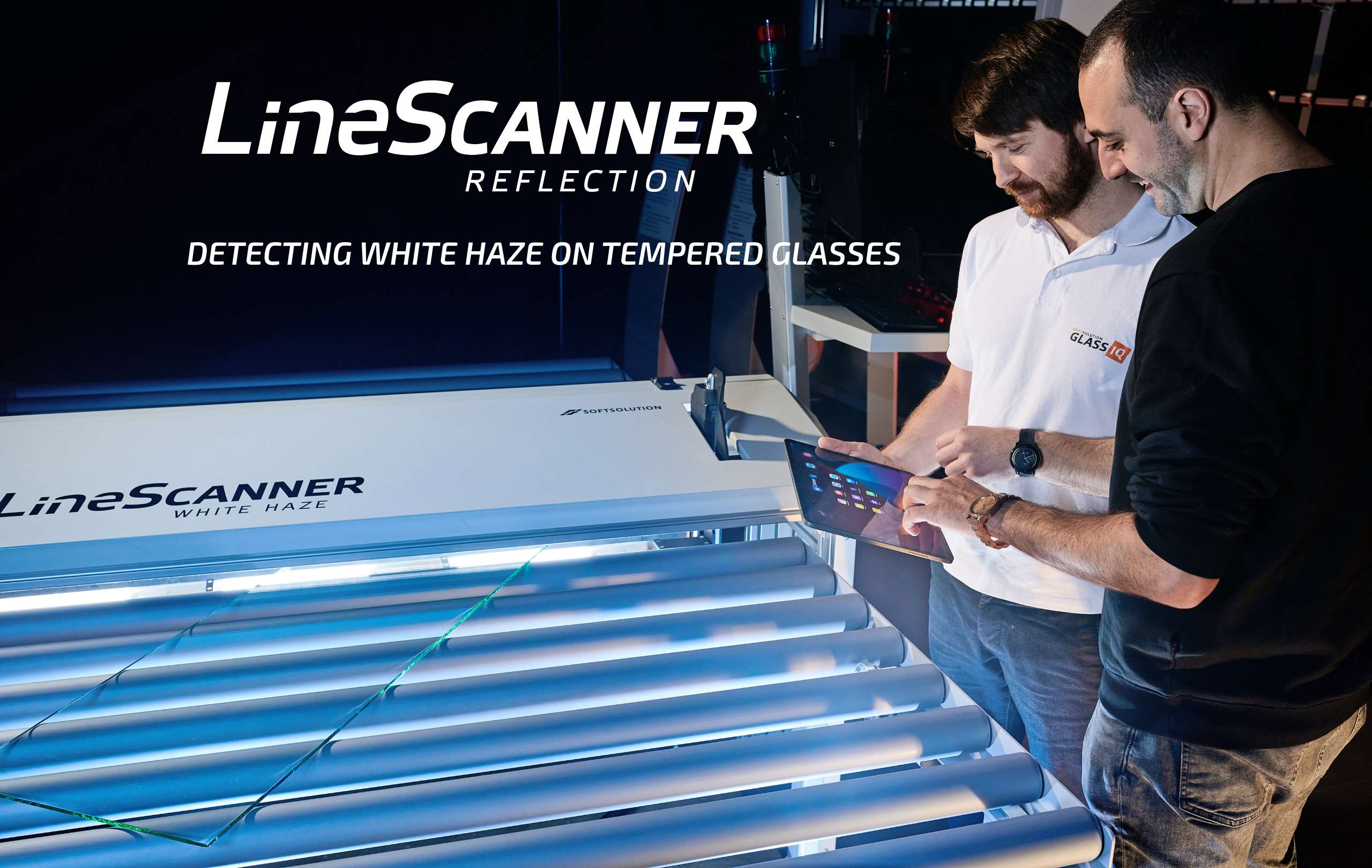

LineScanner Reflection

Detecting white haze on tempered glasses.

White haze has been a hot topic in the glass industry for decades. Correcting white haze related issues can be a bit like hunting a ghost – as there’s a huge amount of different items that can affect the creation of white haze in the tempering process. At the same time, detecting white haze has been based completely on subjective manual inspection.

A critical defect that is difficult to see with the human eye can now be easily made visible.

But what is white haze?

- Foggy areas or repetitive stripes on glass surface, also called “ghosting”.

- Most commonly seen as a long blemish in the center of the glass.

- Can also appear near the edges, corners or even all over the glass.

- Phenomenon with no official standards. Purely a cosmetic issue.

What causes white haze?

- Pre-processing

Up to 80% of white haze issues are caused during the processes prior to tempering. Only around 20% appear as a result of tempering itself. Most white haze is nothing more than glass dust generated by the edge grinding process. The dust should be washed off the preprocessed glass in the washing machine. However, if the water wasn’t cleaned properly beforehand and starts recirculating, it creates a fine dust layer on the glass. During tempering, this layer fuses onto the glass and appears as white haze. - Mechanical issues

The most common reason for white haze in the tempering process itself is residue on the furnace rollers. This residue then causes tiny scratches on the glass surface. If this is the case, examine the roller surfaces.

The Solution:

LineScanner Reflection

Making white haze visible is the key for reliable and stable detection.

There is one method where this defect becomes so obvious and visible and that method is reflection. Softsolution developed a unique hardware configuration using reflection based scanning technology. Every image is interpreted by an AI-based algorithm. In cooperation with highly experienced people from tempering industry, the system and software were developed.

To achieve a stable solution of an industrial image processing application, an essential factor related to the hardware used is the illumination. As with our unique LineScanner, for which we have developed a parallel light technology, this topic plays a very important role.

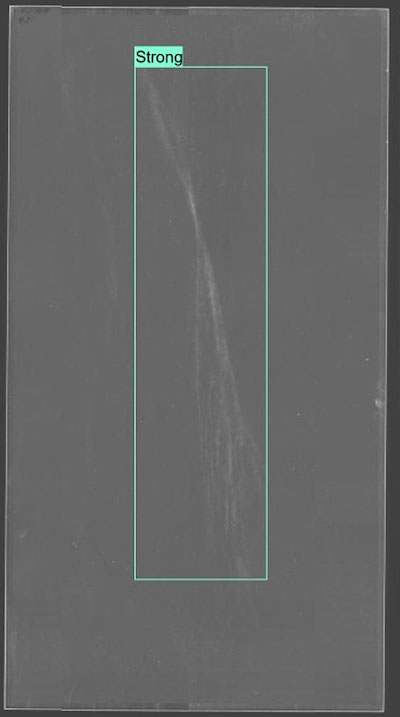

In the first step, we tried to make the very fine scratches/surface changes of the white haze effect visible with high-resolution imaging sensors (400dpi) using extremely short-wave light. At this high resolution (equivalent to 250Mpixels per m² of inspected area), strong white haze effects were visible in reflected light mode. By using a modular design, we can construct hardware of almost any width/height. Thereby a constant resolution is given over the entire acquired scan area.

- unique reflection-based scanning designed by Softsolution

- reliable, stable image acquisition

- AI-based software algorithm developed using thousands of images

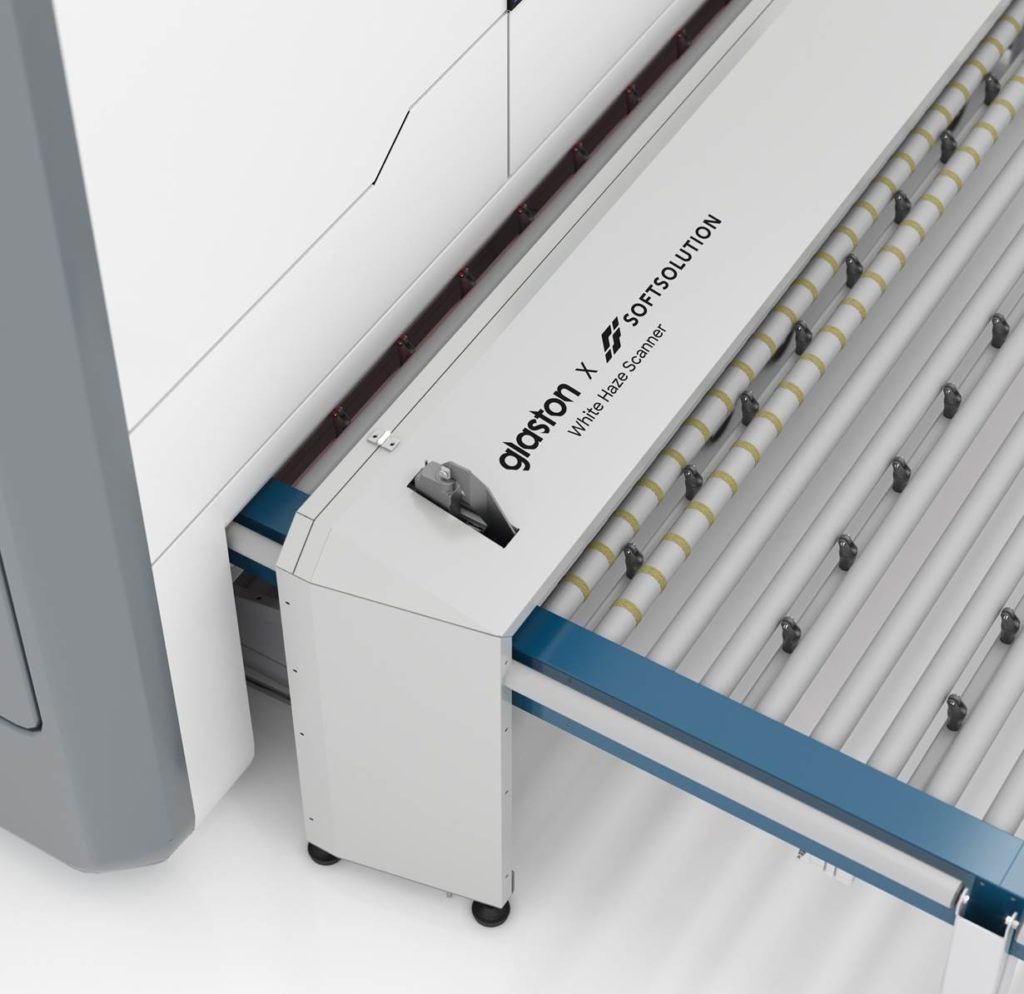

Invented and developed

in cooperation

LineScanner Reflection

for white haze detection

- small footprint

- easy installation

- auto cleaning

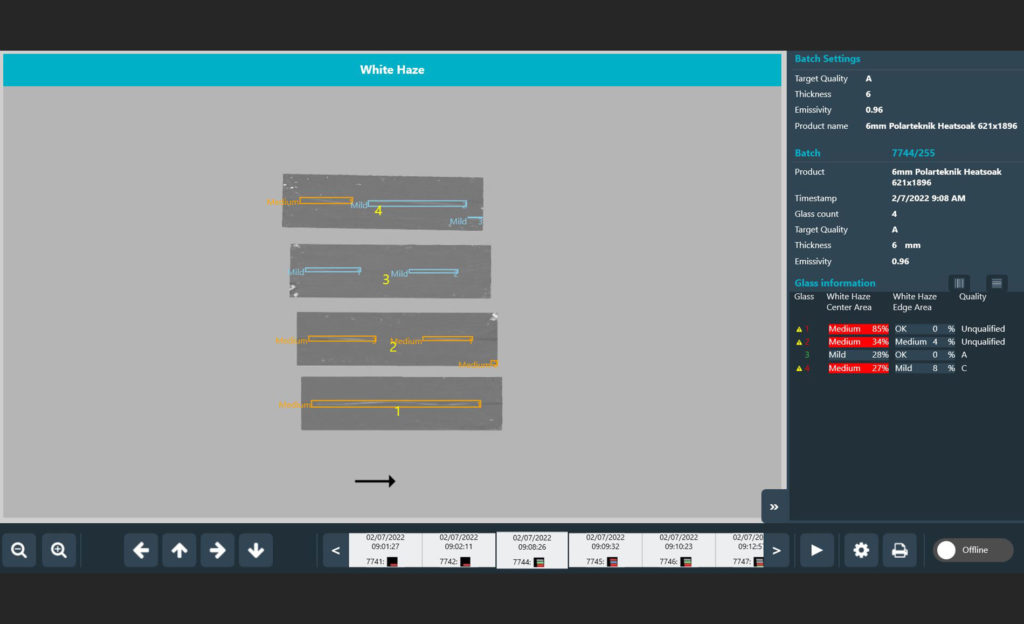

White haze scanner – classification

MILD

Visible with external light source.

Not considered a problem in glass industry, can often be easily rubbed off the glass surface.

MEDIUM

Visible haze with

closer inspection.

Can be unqualified especially for quality oriented costumers.

STRONG

Visible haze.

In many cases categorized as unqualified, especially in high value installations.

We need your consent to load the content of YouTube.

We need your consent to load the content of YouTube.