LineScanner

High-precision scanning technology for quality inspection of glass

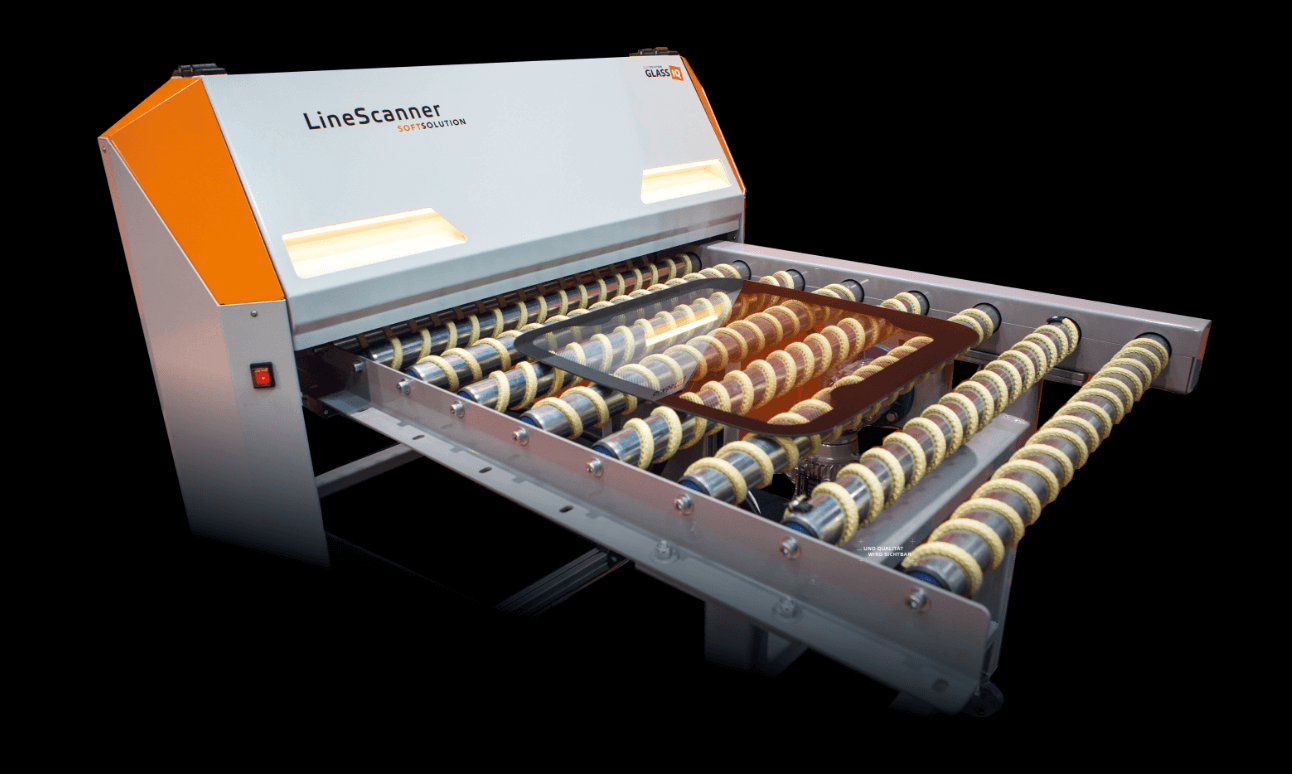

The LineScanner is the solution for all quality inspections of transparent flat glass products such as single sheets, insulating glass, automotive glass, processed glass, polycarbonate or film. LineScanner inspects your products with extreme precision for all defects in quality and dimension. Its flexibility as well as its simple operation and installation allow it to be put into operation quickly and easily with minimum space requirements.

Especially in the glass industry, it’s increasingly important, to meet the high demands of customers and partners. Since years Softsolution deals with the complex issue of checking the quality assessment of flat glass. Therefore we have developed a scanner which will revolutionize also your business!

Interested in our LineScanner?

Scroll down for more details:

Developed in Waidhofen/Ybbs, Softsolution produces unique LineScanners at the highest technical level. Many years of expertise and experience in the glass industry and with over 750 installations worldwide, Softsolution guarantees for excellent glass defect inspection systems on the market. Our LineScanner helps to deliver consistent quality to your customers and thus reduce the complaint ratios.

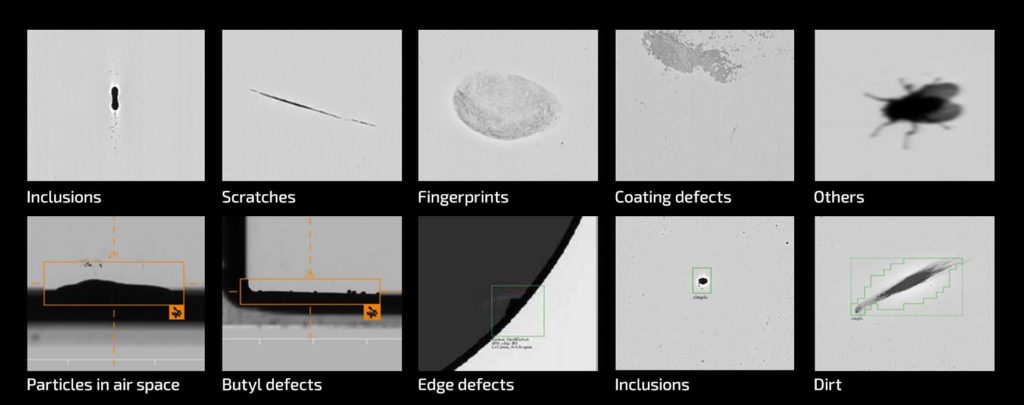

DEFECT ASSIGNMENT WITH AI

Artificial intelligence improves traditional automated methods, including error categorization in the LineScanner software. Our system learns from errors and continuously improves the evaluation. False quality rejects are reduced.

In practice, operators on the line sometimes judge a software decision differently. The software adopts this change and takes it into account in future evaluations. The LineScanner learns from operator feedback and continuously adapts its categorization behavior.

Invest in the Future

Manual glass quality assessment is a thing of the past!

The unique parallel light technology enables the LineScanner to be operated with the same setup to inspect single sheets as well as finished insulation elements both horizontally and vertically. An automatic glass defect inspection system that excels with maximum flexibility and extreme ease of use.

The LineScanner inspects flat glass products for optical defects like scratches, inclusions, edge chips, screen printing, bars as well as dimensional defects with regard to overall dimensions, drill hole diameter and position. Glass thickness, the coating side and element structure can be quickly and easily examined. Thanks to the use of specially developed glass encoders, the position and size of defects can be optimally displayed.

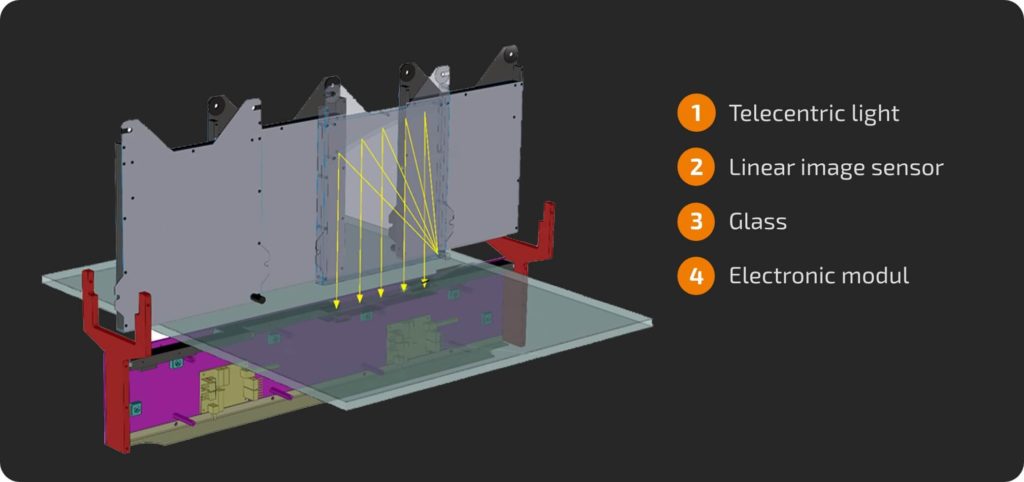

Technological advantages

- Resolutions of up to 200dpi and 16bit technology enabling a highly accurate scan image of the inspected object

- An inspectation with 90° of all areas of the respective object leads to stable and repeatable results

- The proven high-speed and high-resolution technology is based on scanning modules and an optimized parallel light illumination with LED.

AUTOMATed Glass Quality Inspection with the LineScanner All-in-One System

Surface & Edge Quality

Quality inspections at the highest level

The glass quality and edge check detects a wide range of visible defects. These range from scratches and inclusions to coating errors and edge defects (i.e. chips). Each recorded defect is categorized and evaluated using custom quality settings. The simplicity of setting the sensitivity in such a quality inspection tool is imperative. The LineScanner provides the optimal solution in this regard.

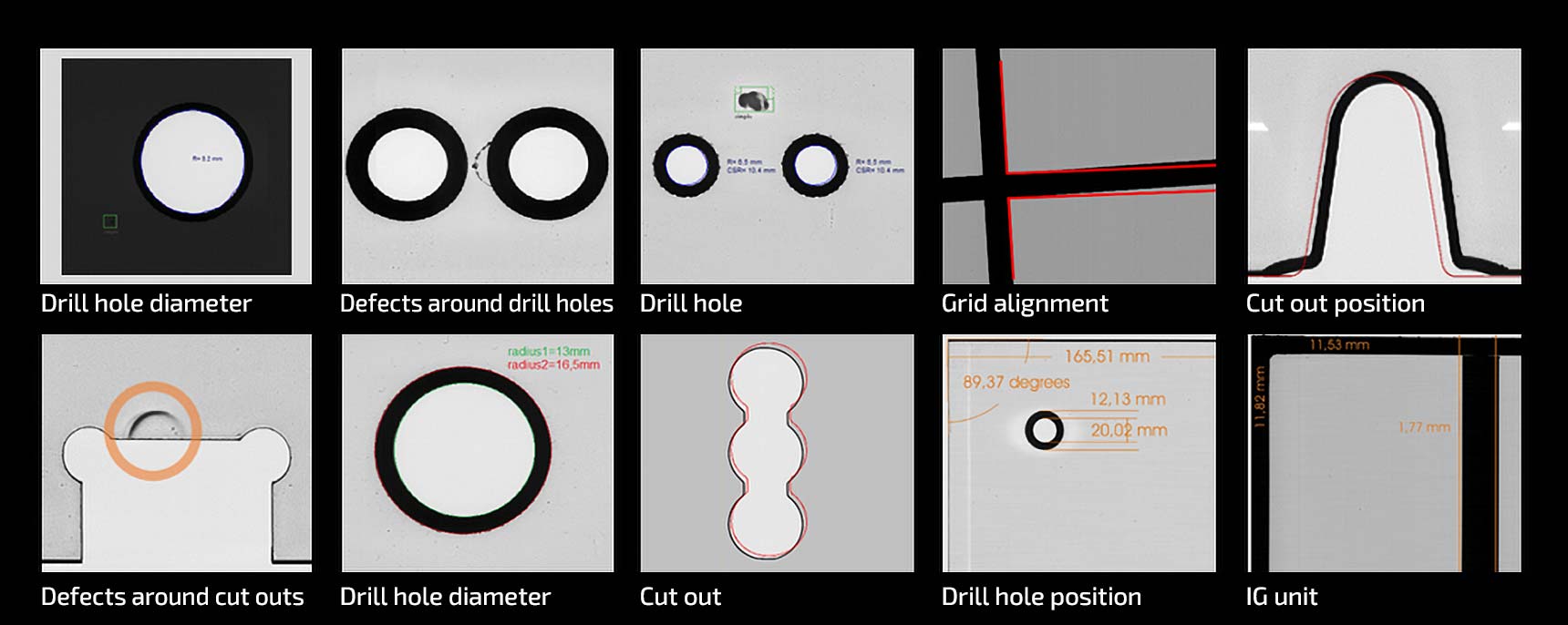

Dimension Control

Experience the new quality of scan technology

Demands for precision size control are constantly increasing and are particularly important for a material such as glass. The LineScanner checks dimensional tolerances inline during the production process – without any effect on the cycle time. Starting with the external contours, inner contours, and the edge cut-outs, the dimension check also inspects drill holes for parameters such as location and diameter. The telecentric imaging by the LineScanner is what makes such a precise measurement possible in the first place and is a basic physical prerequisite.

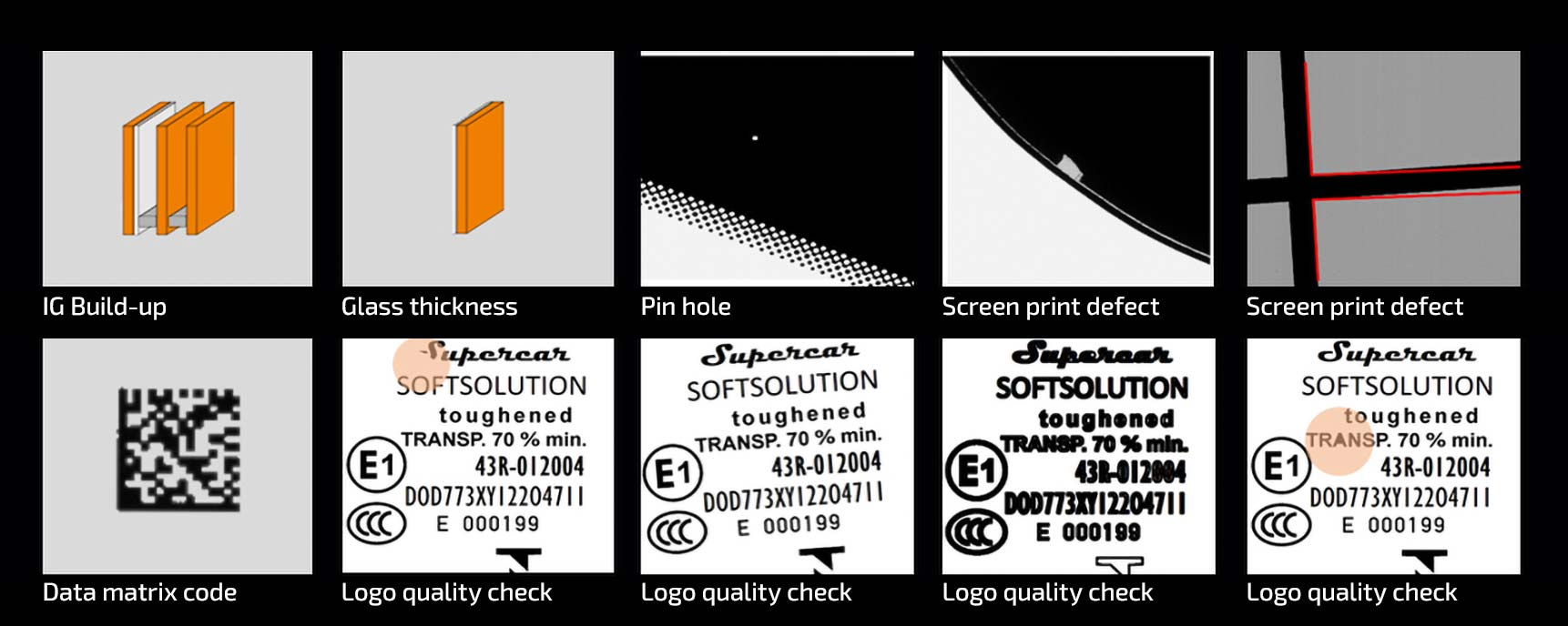

Special Quality Checks

A product with many versatile uses

The LineScanner can handle any challenge, no matter how unique. The wishes and demands of our customers show again and again the large performance range of the LineScanner. The quality check of logos, developed specifically for the automotive industry, has now become standard.

- Verify the correct logo

- Logo position and rotation

- Missing parts within a logo

- Ink strength (too much/not enough)

- Detailed errors in graphics

- Screen printing errors

- Correct screen print position

- Glass thickness

- Unit build-up of insulated glass

Tempering Quality

New: Check for anisotropy / isotropy and edge stress

A seamless record of the glass quality is imperative. A lack of useful feedback during the heat-treating process can lead to varying qualities within the final product. The LineScanner provides this feedback by displaying real-time data to the tempering furnace operators. With the help of the LineScanner, companies can now check every heat-treated lite for anisotropic properties – in combination with the thermal imaging – and the edge stresses.

The LineScanner on the tempering furnace checks the following parameters for each glass sheet, in a single scanning process with minimal space requirements:

- Isotropy / anisotropy value [%]

- Edge stress [MPa]

- Glass quality (scratches, inclusions, soiling, coating defects, etc.)

- Edge quality (conchoidal fractures)

- Glass dimensions (drill hole locations, drill hole diameters, corner cut-outs, edge cut-outs, etc.)

- Screen printing quality (pinholes, screen printing position)

- Logo position & logo quality (image-in-image comparison)

- Data matrix interpretation

Dive deeper into anisotropy/isotropy and edge membrane tension and learn what else LineScanner can do for you!

Management Console

The newly developed LineScanner Management Console provides processors with an online overview of the current status of all scanners in production and thus integrates the scanners into the extensive automation and workflow control. This software tool records the quality and quantity of produced and scanned slices per line and gives a quick overview of all scanners in operation.

The LineScanner Management Console provides the user with the most important data (status of the line, service requirements – also foresighted – as well as current production figures with corresponding quality results) in real time. A complete documentation of the glass quality is indispensable and, thanks to lot and Industry 4.0, will be even easier in the future.<

We are proud to announce that we did add a new feature, which allows defining alarms/notifications now. If production quantity or quality exceeds limits, people will be notified immediately.

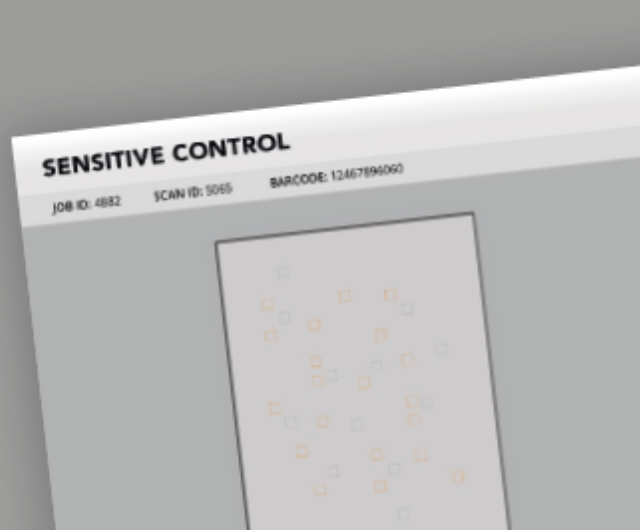

Archive Database

Data capture and analysis made easy. Thanks to the archive, scanned glass items can be easily and quickly stored and archived in a MySQL database. This feature documents and archives all the work processes, quality settings and every single detail pertaining to a glass item. Furthermore, all the required data are available for subsequent analysis.

The LineScanner archiving software is a standalone application that can be used to search for specific glass items in the database (for example by customer, barcode, order number, line item number, etc.) and to then provide a visual representation of them.

Linescanner Features

We need your consent to load the content of YouTube.

We need your consent to load the content of YouTube.