CulletScanner

Automatic Fragmentation Image Analysis with optional anisotropy and edge stress function

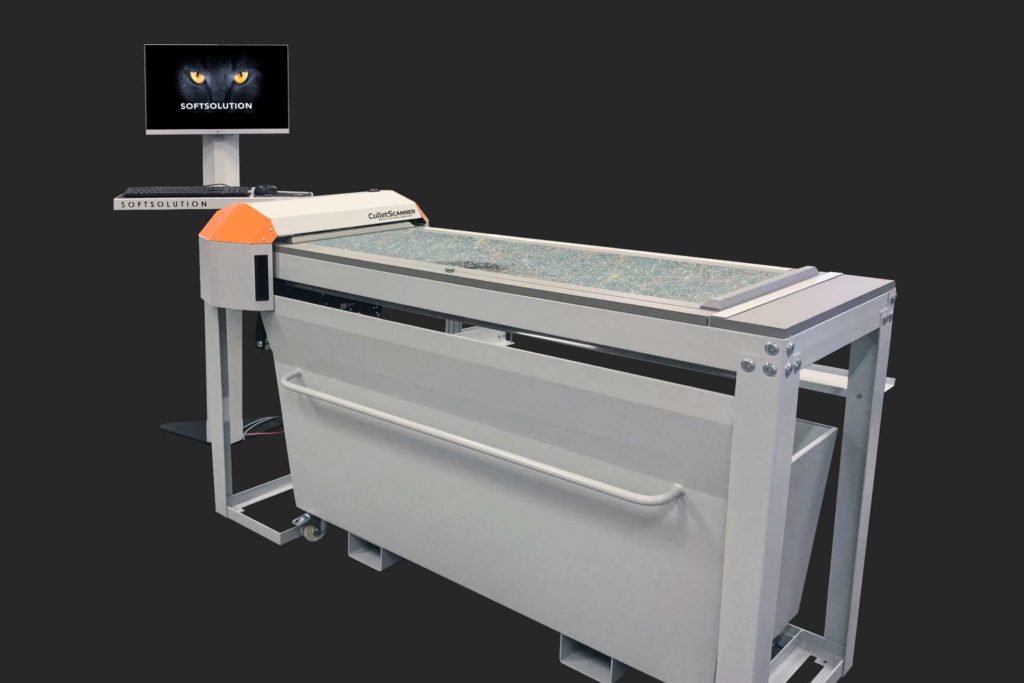

The CulletScanner from Softsolution with new tilt function scans with the highest resolution every tempered glass, such as architectural-, automotive-, window glasses and shower doors and eg. Each fragment is viewed from a 90° angle and the entire fragmentation image of a test lite is precisely and completely evaluated within seconds.

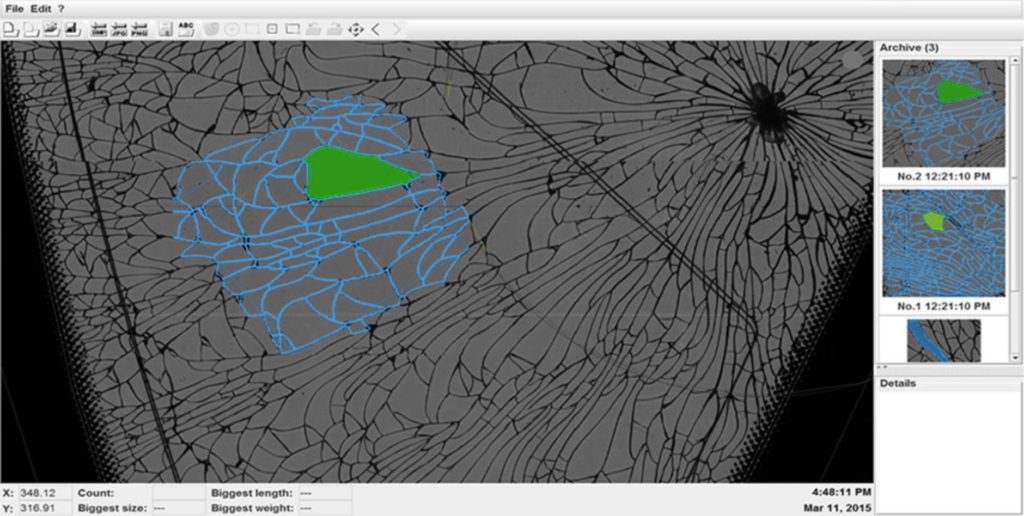

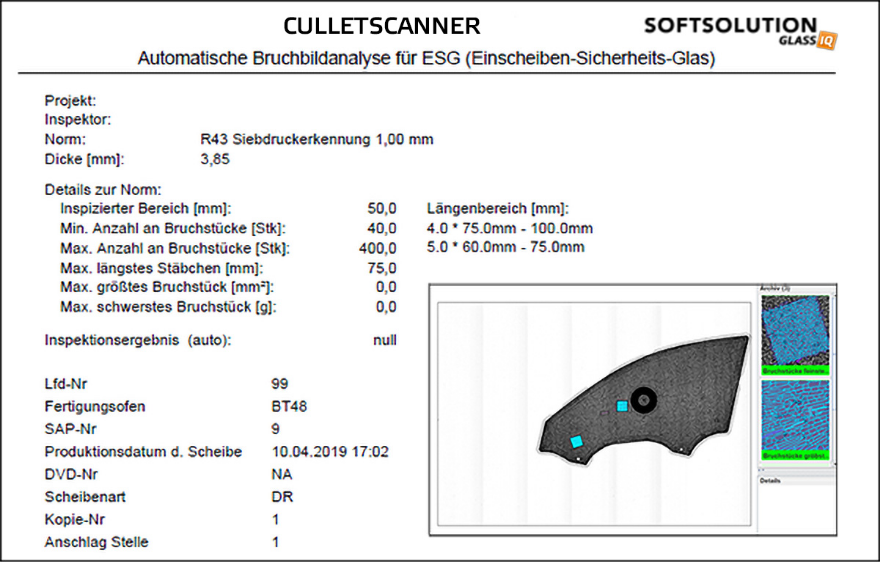

The position, size, length, area and weight are determined and each scan of a fragmentation image is digitally stored with the highest precision and sharpness. Exclusion areas along the outer contour and the point of impact are of course also taken into account. A certificate printout in PDF format is then generated automatically.

Scroll down for more details:

The new view of things

CulletScanner by Softsolution

Fully automated fragmentation image analysis for different types of glass

Capture of the longest, largest and smallest fragments – many standards available

Precise calculation of length, surface area and weight of every single fragment

Edge stress and correlation to surface tension (approximation)

Anisotropy

Automatic Counting

Put your mind at ease with the use of innovative technology

The CulletScanner analyzes the entire glass lite and checks areas with the most, fewest, largest and longest fragments fully automatically. These positions are highlighted and analyzed once more.

The associated CulletScanner software provides all established, familiar standards in this field (EN 12150, EN 14179, EN 14428, EN 31129.NFF, R 43, ANSI Z97.1-2004, CAN/CGSB-12.1M). The CulletScanner counts consistently, stably and comprehensibly!

One scan – a lot of useful data

By using the software, all data are subsequently evaluated and stored. A certificate print lists the results of the fracture image analysis including all analysis areas, the associated order, the type of furnace and of course an overall result.

Technical Details

Individual sizes

Electronically driven scan bridge, swiveling, fully automatic

Based on true scanning technology, up to 200 dpi Image storage in highest resolution – no quality loss

Certificate printing

Automatic counting and analysis of each cullet

Archiving

Saves each test in a digital CulletScanner project file

- Individually configurable

- Standard table for glass sizes of 1100 x 360 mm (The CulletScanner can also be manufactured in any custom size)

- Inspection of individual sheets

- Glass must have transparency of 15 – 99 %.

- Maximum scanning speed: 20 metres/minute

- Glass thickness: 2.3 – 20 mm

- Power supply: 230 V, 16 A, 50Hz, single phase, separate neutral conductor and earthing

- Operating system: Windows 7 or higher

Archive & Certificate

Every fragmentation test will be digitally stored and archived in highest precision and definition.

There is no need to store blue prints or something like this, since the full report can be reopened at any time without any loss of quality.

Finally a PDF certificate with all necessary information about the scanning process is generated.

Put your mind at ease with the use of innovative technology.

Scanning at a high resolution, the CulletScanner scans all fracture patterns and analyzes them precisely within seconds.

We need your consent to load the content of YouTube.

We need your consent to load the content of YouTube.