Intercept defects before shipment.

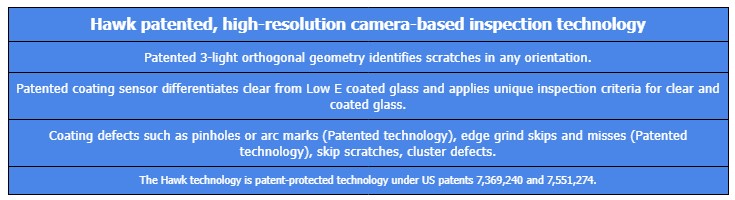

Hawk™ 4 is a high-resolution camera-based inspection system. The Hawk inspects both front and rear surfaces of monolithic or laminated glass as it moves down the fabrication line

» Key Application: Tempering Lines, Coating Lines, IG Lines

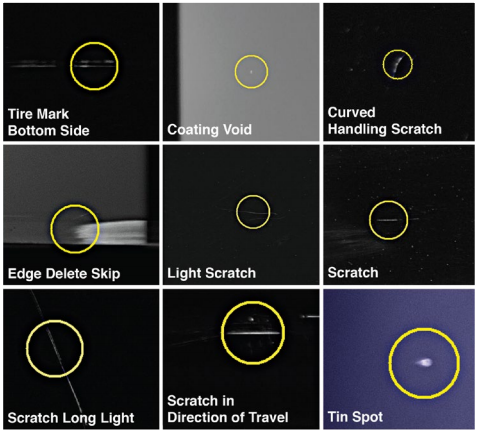

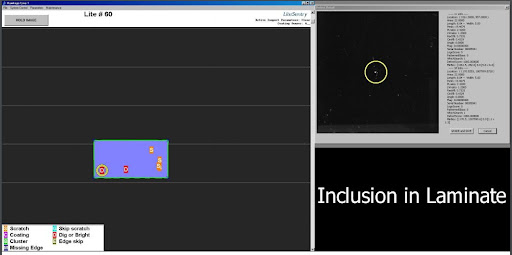

High-resolution cameras find all defect types in dark field & bright field dual lighting systems

Defects are graded based on easy-to-use criteria

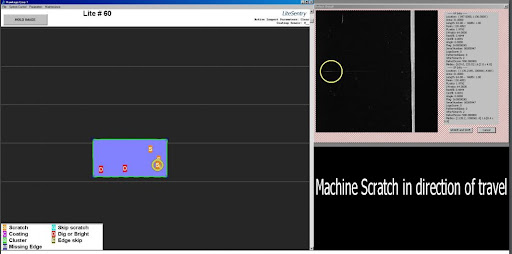

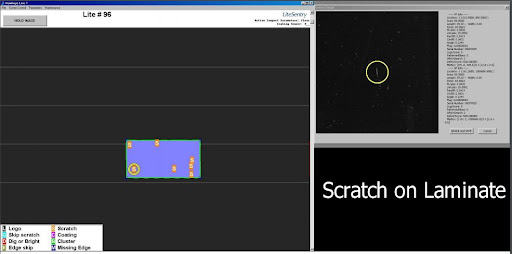

Defects are displayed on the screen when the part arrives at the inspection station or past a certain point on the conveyor

Actual Images from Hawk

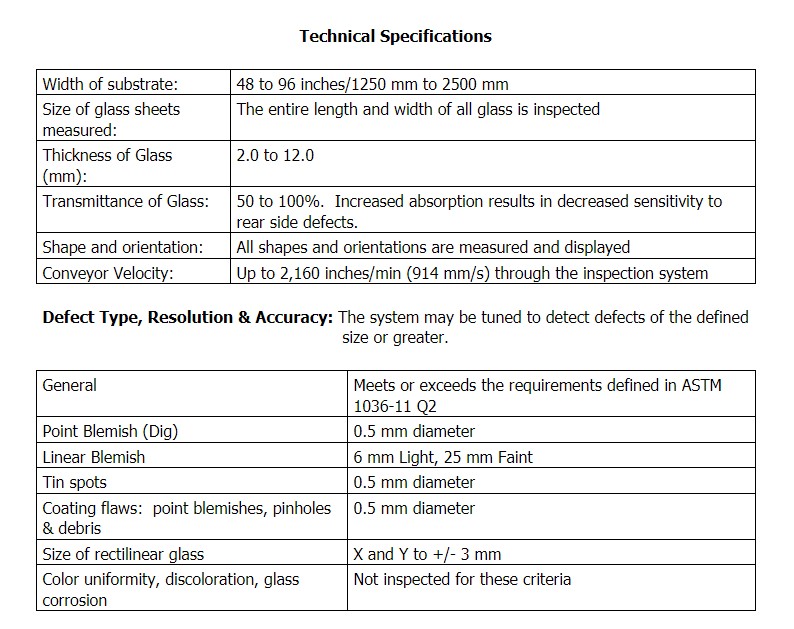

Technical Specifications

| Width of substrate: | Up to 96 inches/2500 mm |

| Size of glass sheets measured: | The entire length and width of all glass is inspected |

| Thickness of Glass (mm): | 2.0 to 12.0 |

| Transmittance of Glass: | 50 to 100%. Increased absorption results in decreased sensitivity to rear side defects. |

| Shape and orientation | All shapes and orientations are measured and displayed |

| Conveyor Velocity: | Up to 2,160 inches/min (914 mm/s) through the inspection system |

Defect Type, Resolution & Accuracy: The system may be tuned to detect defects of the defined size or greater

| General | Meets or exceeds the requirements defined in ASTM 1036-11 Q2 |

| Point Blemish (Dig) | 0.5 mm diameter |

| Linear Blemish | 6 mm Light, 25 mm Faint |

| Tin spots | 0.5 mm diameter |

| Coating flaws: point blemishes, pinholes & debris | 0.5 mm diameter |

| Size of rectilinear glass | X and Y to +/- 3 mm |

| Color uniformity, discoloration, glass corrosion | Not inspected for these criteria |