Finding the Right Sensitivity for Your LineScanner: A Guide

When it comes to using a LineScanner for quality control, one of the most crucial decisions is determining the appropriate sensitivity level. Should the scanner detect even the tiniest defects, or should it focus on identifying only significant ones?

Our experience shows that customers generally prefer the LineScanner to flag only “relevant” defects—those that are important and impactful, while ignoring minor or acceptable imperfections. This approach helps in avoiding unnecessary alarms and maintaining efficiency in the inspection process.

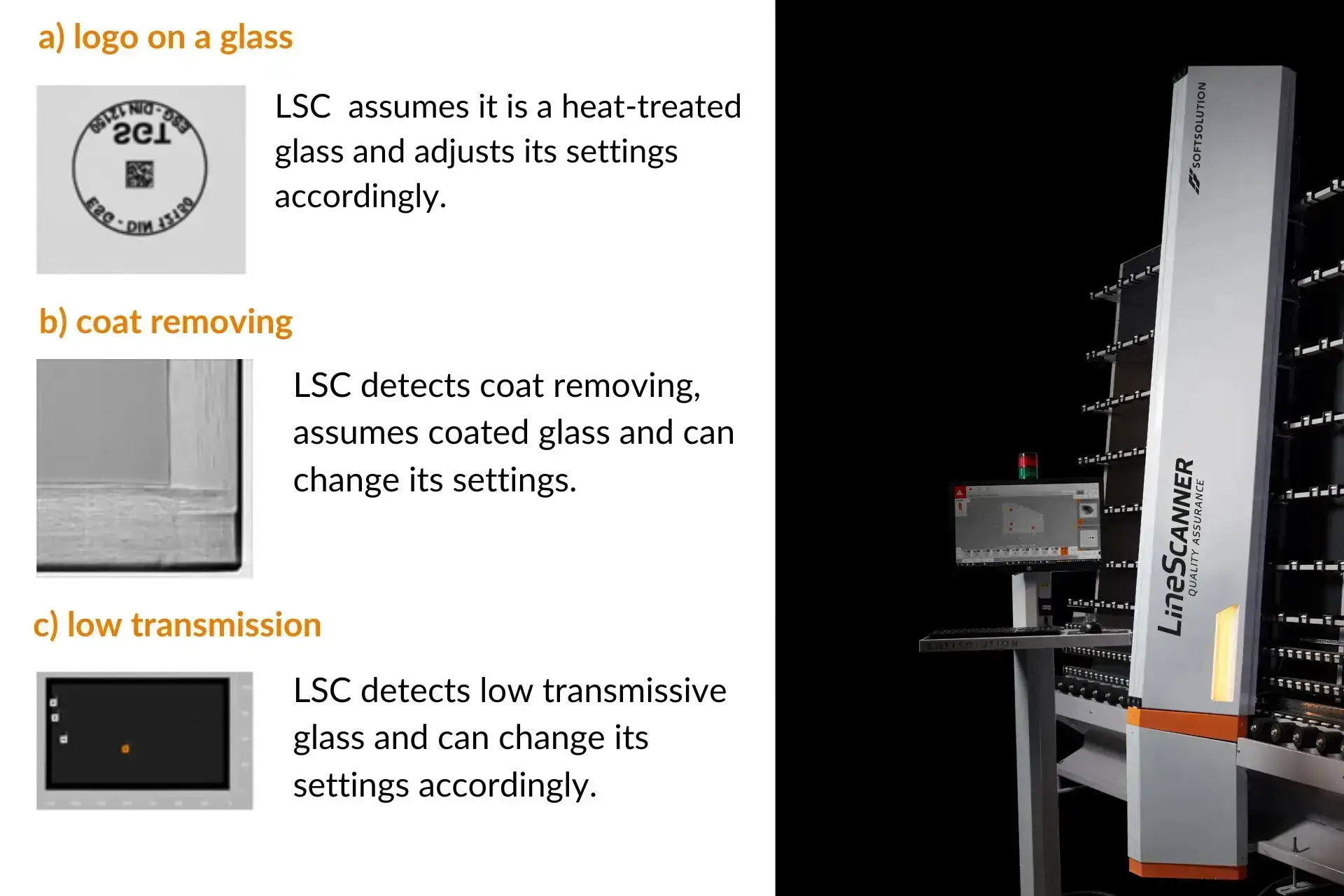

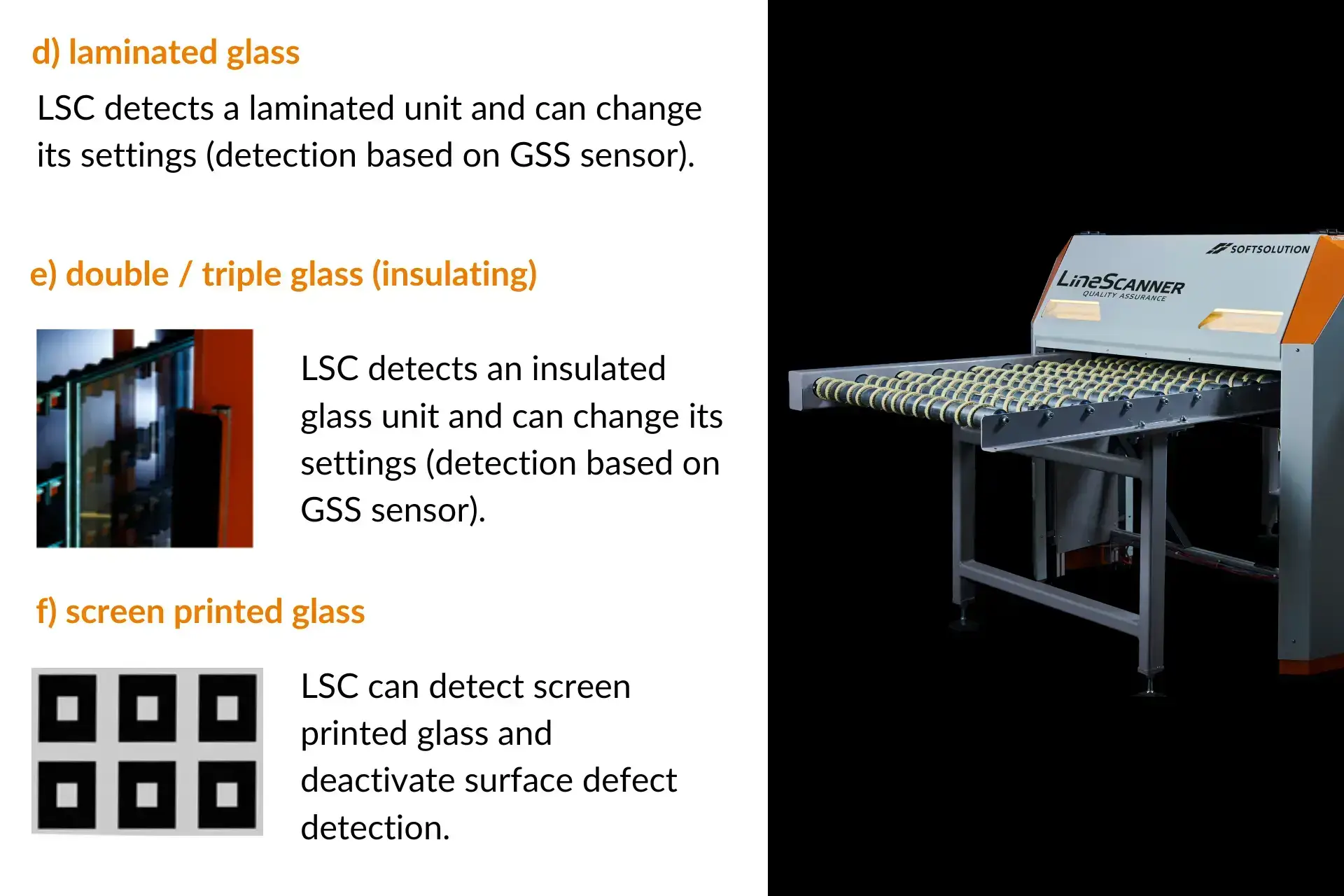

However, we also recognize that different types of glass require varying levels of sensitivity. For instance:

- High Sensitivity for Float Glass: A well-washed float glass can withstand a higher sensitivity setting, allowing the LineScanner to detect very fine defects.

- Moderate Sensitivity for Tempered Glass: Tempered glass often displays certain acceptable effects, such as small dots, which should not be flagged as defects.

To address these diverse needs, our LineScanner offers two powerful solutions:

- Adjustment Based on Interface Information:

The LineScanner can adjust its sensitivity based on the type of glass it is inspecting. By receiving information about the glass type through various interfaces, it can automatically apply the appropriate quality settings. This ensures that the scanner is always tuned to the right level of sensitivity for the glass being processed. - Self-Detection of Glass Type:

In addition to manual adjustments, the LineScanner can also automatically detect the type of glass it is inspecting. This self-detection capability allows it to autonomously adjust its sensitivity settings, ensuring optimal performance without the need for manual intervention.

With these features, the LineScanner offers a versatile and efficient solution for maintaining the right balance of sensitivity in your glass inspection process. Whether dealing with pristine float glass or robust tempered glass, the LineScanner ensures that only relevant defects are flagged, streamlining quality control and enhancing overall productivity.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information