Distortion

// Check for roll wave, edge kink, local bow, pocket, side kink, hammer, bird’s eye, picture framing, belly banding, edge lift, corner lift, bi-stability, saddle bow, oil-canning, soft-center, center kink, vertical kink

What is Distortion?

Distortion in glass is a critical factor that influences its optical and structural properties. It can arise from manufacturing processes, thermal effects, or intentional design choices. Minimizing distortion is essential in applications where precision and clarity are paramount, such as in high-quality optics and modern architectural designs. Understanding and controlling distortion allows for the production of glass that meets the stringent requirements of these fields.

The Role of Distortion in Glass

Distortion in glass refers to any deviation from the perfect flatness or smoothness of the glass surface that can affect the clarity and accuracy of transmitted images. This type of distortion is significant in various applications, particularly in optics and architecture. Here’s how distortion plays a role in glass:

- Optical Clarity: For applications like lenses, windows, and other transparent surfaces, any distortion in the glass can affect the way light passes through, leading to blurry or warped images. High-precision optical instruments require glass with minimal distortion to ensure accurate imaging.

- Architectural Glass: In buildings, glass distortion can affect both the aesthetic and functional aspects. Distorted glass can lead to reflections that are not true to the actual surroundings, causing visual discomfort or misrepresentation of the view. It can also impact the structural performance by causing uneven stress distribution.

- Manufacturing Process: The production of glass involves processes such as floating, drawing, or rolling. Any imperfections in these processes can introduce distortions. For example, during the float glass process, if the molten glass is not perfectly leveled, it can lead to thickness variations and surface waves, which cause optical distortion.

- Thermal Effects: Temperature changes can cause glass to expand or contract, leading to warping or bending. This thermal distortion can be a concern in environments with fluctuating temperatures, affecting both the performance and longevity of the glass.

- Curved Glass: In some architectural designs, curved glass is used for aesthetic or functional reasons. The bending process must be carefully controlled to minimize distortion, ensuring that the curvature does not introduce optical aberrations or structural weaknesses.

Distortion in Glass Quality Control

Quality control for glass production involves rigorous testing and inspection to ensure that the glass meets specific standards for optical clarity, strength, and overall performance. Distortion is a key factor that affects the quality of glass, and controlling it is crucial in many applications. Here are the primary methods and considerations for managing distortion in glass quality control:

1. Visual Inspection

- Manual Inspection: Skilled inspectors visually examine the glass for any noticeable distortions, waves, or warping. This is often the first line of defense in quality control.

- Automated Optical Inspection: Advanced systems use cameras and software to detect and quantify distortions. These systems can provide more consistent and objective assessments compared to manual inspections.

2. Measuring Techniques

- Osprey 10 measures ALL TYPES OF DISTORTION (roller waver, edge kink, picture framing, pocket hammer distortion, corner lift, center kink, vertical kink, oil canning) in milidiopter as well as peak to valley in mm.

Top glass fabricators use mD to produce flat glass because it is a better representation of distortion.

The Osprey provides accurate results for both mD and peak-to-valley in mm or inches. - 1.Peak to valley measures the depth of distortion

- 2.Millidiopter measures the shape of distortion

3. Quality Standards and Specifications

- ASTM Standards: The American Society for Testing and Materials (ASTM) provides standards for evaluating glass distortion, such as ASTM C1048 for heat-treated flat glass.

- EN Standards: European standards like EN 12150 for thermally toughened safety glass include guidelines for acceptable levels of distortion.

4. Manufacturing Process Control

- Float Glass Process: Ensuring the molten glass floats on a perfectly level bed of molten tin to produce flat, distortion-free glass.

- Annealing and Tempering: Proper control of cooling rates during annealing and tempering to prevent residual stresses that can cause warping or distortion.

- Continuous Monitoring: Implementing real-time monitoring systems throughout the manufacturing process to detect and correct any deviations that could lead to distortion.

Effective quality control for glass distortion involves a combination of visual inspections, precise measurement tools, adherence to standards, and controlled manufacturing processes. With the Osprey10, manufacturers can produce high-quality glass that meets the stringent requirements of various applications, ensuring both optical clarity and structural integrity.

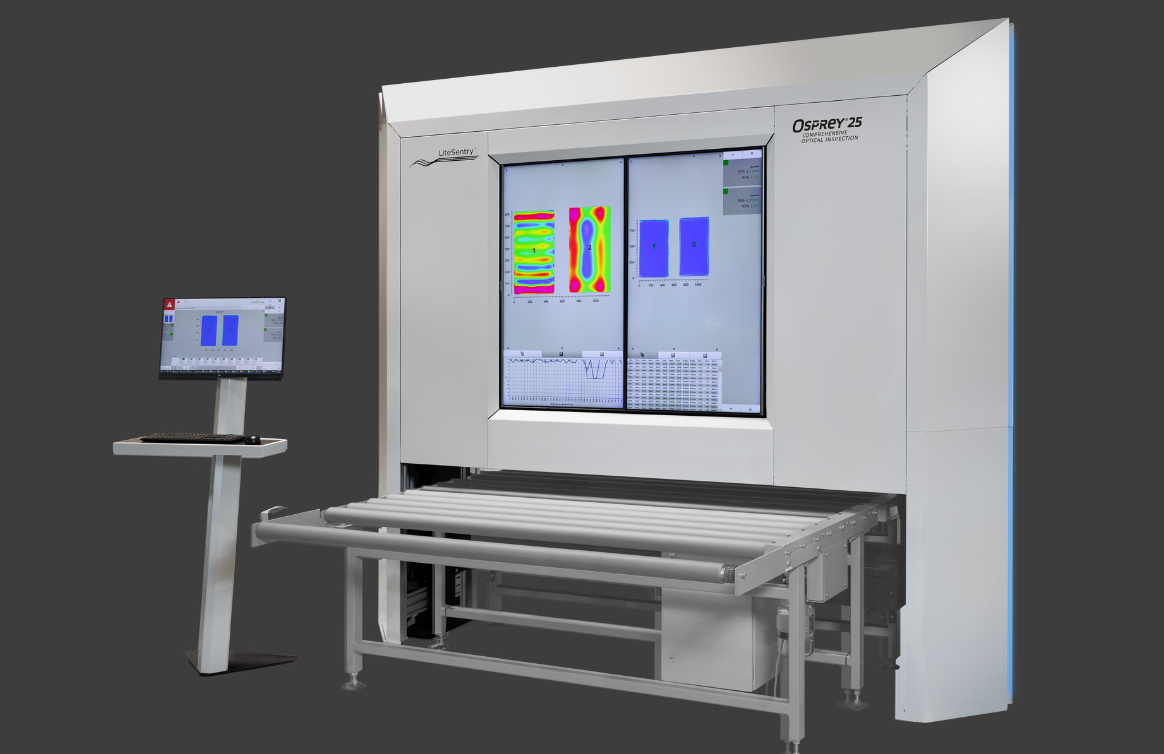

Osprey®25 Inspection System by LiteSentry

The premiere distortion, anisotropy, and surface quality inspection in a single footprint

Learn moreYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information