Understanding Anisotropy and Isotropy in Glass Quality Control

// Check for maximum observable iridescence, strain marks, heat staining and average or residual stress.

What is Anisotropy / Isotropy?

Anisotropy in glass refers to the property where the material exhibits different physical properties in different directions. This often results in visual phenomena like iridescence, which occurs when unbalanced residual temper stress within the glass selectively reflects naturally polarized light, such as that from the blue sky or water reflections.

Glass is considered isotropic when its properties such as refractive index, thermal expansion coefficient, and mechanical properties (like elasticity and strength) are the same in all directions. This means that if you were to measure any of these properties along different axes within the glass, you would get the same result. Understanding isotropy in glass helps in engineering applications and material design, ensuring that the material performs predictably and reliably in various uses ranging from architectural to scientific instruments.

Key definitions:

Anisotropy: The condition where optical properties, primarily the index of refraction, differ in various directions.

Birefringence: Orientation-dependent differences in the index of refraction, usually due to stress.

Retardation: A measure of birefringence in nanometers (nm).

Iridescence: A ghostly reflection of polarized light resulting from varying stress imbalances in glass.

Importance of Glass Quality

In industries reliant on heat-treated glass, such as construction and automotive manufacturing, maintaining consistent glass quality is essential. Variations in glass quality can lead to significant safety concerns and aesthetic issues. Anisotropy, a phenomenon where glass exhibits different properties in different directions, is a critical factor to monitor. Conversely, isotropy indicates uniform properties throughout the glass. Identifying and addressing anisotropy during the production process can significantly enhance the reliability and performance of the final product.

The Role of Anisotropy in Glass Performance

Anisotropy in glass typically manifests as areas with varied stress distributions, which can affect the strength, clarity, and durability of the glass. These variations can result from uneven cooling or improper handling during the tempering process. Anisotropic glass may display optical distortions, such as iridescence or birefringence, which can compromise both the structural integrity and visual appeal of the glass. Therefore, detecting and minimizing anisotropy is crucial for producing high-quality glass products.

Enhancing Product Reliability

By leveraging the capabilities of the LineScanner, companies can achieve greater consistency in their glass products. The ability to detect and address anisotropy ensures that each glass pane exhibits uniform properties, enhancing its performance and reliability. This technological advancement not only improves product quality but also optimizes production efficiency, reducing waste and minimizing the need for rework.

Check Anisotropy and Isotropy with LineScanner and Osprey 10

Anisotropy in glass might sound complex, but it’s a crucial factor in ensuring the quality and appearance of glass products. LiteSentry – Softsolution uses two independent systems for anisotropy testing: the LineScanner and the Osprey 10.

The LineScanner technology revolutionizes the way anisotropy is detected and managed during glass production. By providing real-time data to tempering furnace operators, the LineScanner enables immediate corrective actions, ensuring a consistent heat-treating process. This advanced system scans each heat-treated lite, measuring anisotropic properties and detecting edge stresses. The integration of thermal imaging allows for a comprehensive assessment, ensuring that any deviations are promptly identified and rectified. The continuous feedback from the LineScanner helps maintain stringent quality control standards. Operators can monitor the uniformity of the glass and make necessary adjustments during the heat-treating process. This proactive approach reduces the likelihood of defects and ensures that each piece of glass meets the required specifications.

LiteSentry’s Osprey 10 is on the frontline, expertly measuring anisotropy alongside other vital parameters like distortion and flatness. The Osprey 10 helps to unveil these ghostly patterns, ensuring that each glass sheet processed through tempering furnaces is free from unwanted distortions and meets the industry’s stringent standards. By doing so, LiteSentry’s Osprey 10 is making strides in maintaining the uncompromised quality of glass.

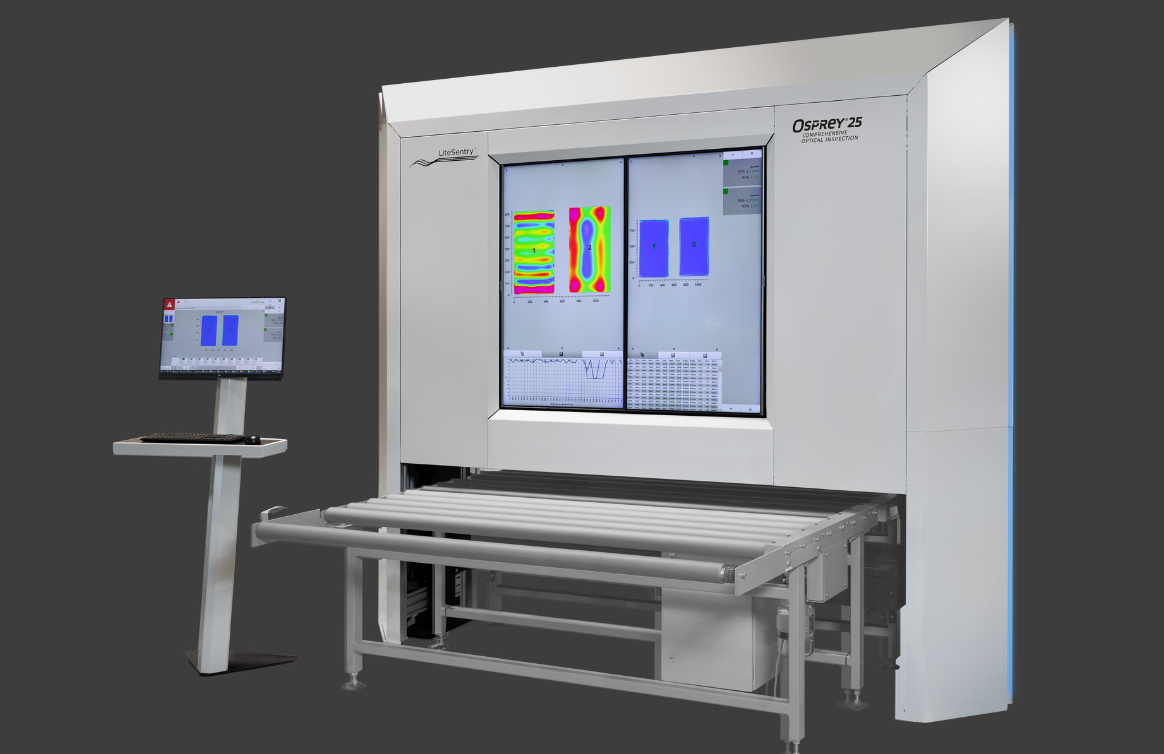

Osprey®25 Inspection System by LiteSentry

The premiere distortion, anisotropy, and surface quality inspection in a single footprint

Learn more

LineScanner by Softsolution

All in one quality inspection with worldwide unique real scanning technology

Learn moreYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information